Media Center

A multimedia mosaic of moments at GIST

GIST Excellence

[Press Release] GIST is set to develop a 4D printing simulator

- 엘리스 리

- REG_DATE : 2015.09.04

- HIT : 763

Stepping beyond 3D to the 4D printing age!

GIST is set to develop a 4D printing simulator

Professor Yong Gu Lee (front left) who is primary researcher along with Professor Jong Ho Lee (behind left), Professor Jae Hun Seol (front center), and the team members.

□ 3D printing has attracted enormous interest for its potential myriad of uses, not to mention its valuable economic impact. GIST researchers are now developing a 4D printing technology simulator that incorporates ‘time’ as an integral factor of the printing process.

The project was selected by the Ministry of Science, ICT and Future Planning (director Yang Hee Choi) and Institute for Information & Communication Technology Promotion (director Sang Hong Lee) and will receive 1.9 billion won in research funds for 3 years.

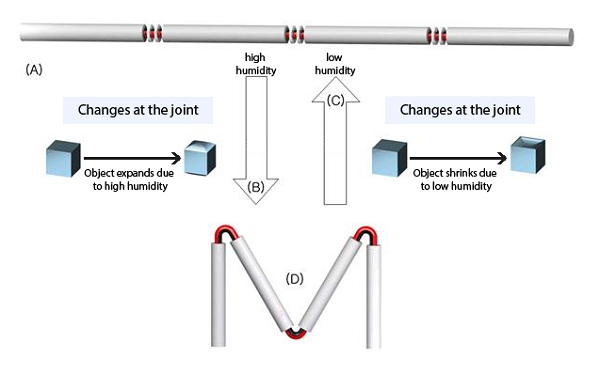

□ 4D printing technology utilizes the 4th dimensional concept of ‘time’ in conjunction with conventional 3D printing technology. The resulting 3D object is created in a manner that utilizes reactions to environmental factors.

Figure 1. 4D printing concept: (A) object from 3D printing. (B/C) Materials used at the joints transform due to humidity changes and it transforms to the specific form (D) as the time progress.

Applying this 4D printing technology can dramatically increase the size of the printed object, which is currently limited by the output capacity of 3D printers. For example, a 30 cm cube can be transformed into a much larger object, such as a chair or a car bumper.

4D printing may be applied to various fields that has spatial constraints, such as in the construction, production, or in outer space. According to the US market research firm ‘Markets and Markets’ which has recently published a market forecast report from 2019 to 2025, 4D printing is expected to have a market value of approximately $600 million (approximately 710 billion won) by 2025.

□ The core technology of 4D printing depends upon knowing how to print the initial 3D object to produce the final desired results. GIST research team will develop a software simulator program that can predict changes over time to an object"s form depending upon physical properties and external environmental factors. With this information, the researchers can determine the initial shape of an object to be printed to obtain the final desired form of that object.

□ The research will be divided by several teams of professionals. Professors Yong Gu Lee and Sung Il Ham’s team will focus on developing the 4D printing software simulator and a dedicated web server. Professor Jong Ho Lee’s team will seek to discover new smart materials that can be used in 4D printing and will standardize the physical characteristics of those smart materials in accordance with environmental factors, such as temperature and humidity. Professor Jae Hun Seol’s team will also search for new smart materials and will also create a database of various 3D structural designs.

The team plans to develop a standardized software simulation program that is easily programmable with user inputs, such as external environmental factors and the materials being used in the printing process. They will also build a web server to more easily share their database with other researchers.

□ Professor Yong Gu Lee said, “There are excellent research results and patents for 3D printing already, but 4D printing technology is only in its infancy. With this software simulator development, Korea will be at the leading edge of 4D technology development in the world."