Media Center

A multimedia mosaic of moments at GIST

GIST Excellence

[Press Release] Prof. Kwanghee Lee"s Team Develops Flexible and Transparent Electrodes

- 정명식

- REG_DATE : 2015.03.26

- HIT : 1105

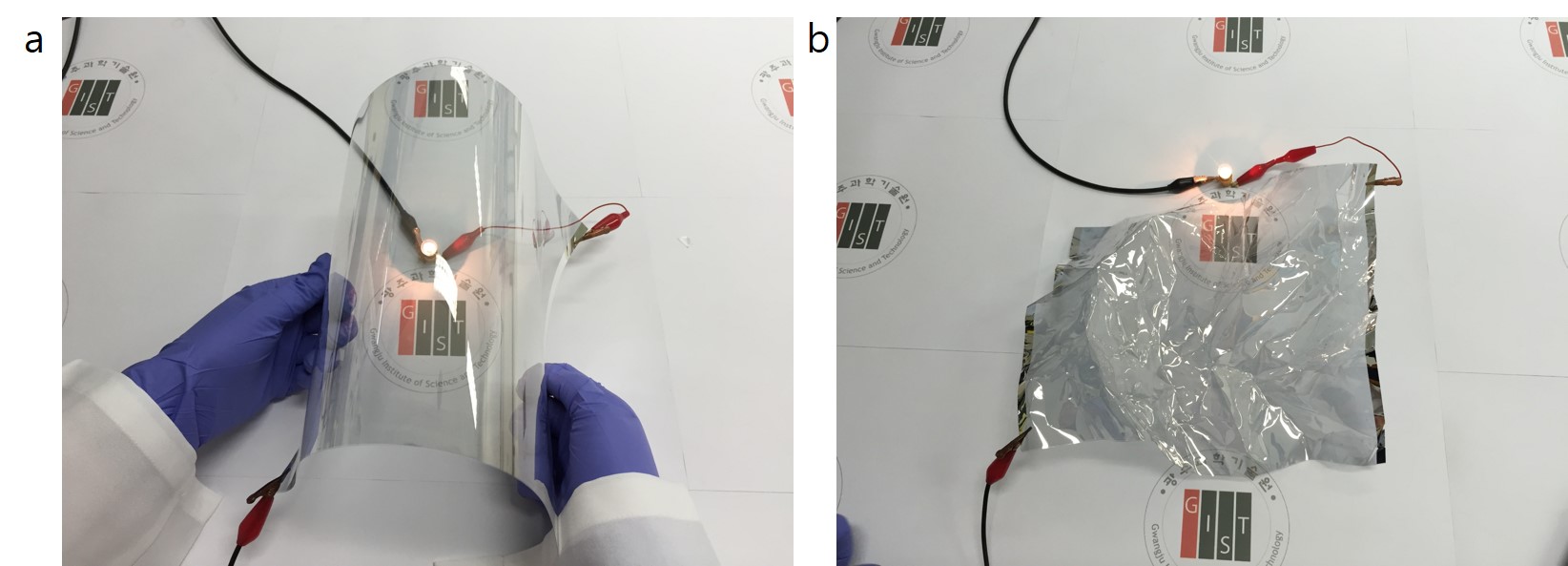

New Transparent Electrodes Foldable Over 1000 Times like Paper

Study to Help Quicken Commercialization of Flexible Electronics

A Korean research team has developed flexible and transparent electrodes

that satisfy the standard specifications, namely a transmittance of 90% or

higher in the visible range and a sheet resistance of 10 Ω/sq or lower. Their

research is expected to help pave the way toward commercialization of flexible

electronics.

The research was led by corresponding author Prof. Kwanghee Lee of GIST

School of Materials Science and Engineering and by co-first authors Dr. Hongkyu

Kang of the Research Institute for Solar and Sustainable Energies (RISE) and

Ms. Suhyun Jung, a doctoral student at GIST School of Materials Science and

Engineering. This work was supported by the National Research Foundation of

Korea grant, funded by the Ministry of Science, ICT and Future Planning, and by

the Core Technology Development Program for Next-generation Solar Cells of

RISE, GIST. The result was published online on March 19, 2015 in Nature Communications (Title:

Polymer-metal hybrid transparent electrodes for flexible electronics).

Flexible and transparent electrodes are considered a

key component to realize future

ubiquitous electronic devices, such as flexible displays and wearable

electronics. Despite recent research efforts to develop new electrodes, further

enhancement in the performance of the transparent electrodes fabricated on flexible

plastic substrates is still required to meet the standard specifications of a high

transmittance in the visible range and a low sheet resistance.

The research team developed an innovative method to

overcome metal island growth originating from random migration and aggregation

of thermally evaporated metal droplets on substrate surface. By introducing an

amine-containing polyelectrolyte as a metal nucleation-inducing seed layer on

the top of the substrate, the research team created uniform, strong

metallization nuclei on plastic substrates in which the nucleation centers are

densely distributed over atomic-scale distances. As a result, the research team

successfully fabricated extremely flexible, conductive and transparent polymer-metal

hybrid electrodes with unprecedented performances, including a high visible-range

transmittance of over 95%, a low sheet resistance of lower than 10 Ω/sq and an excellent mechanical stability with

a nearly constant resistance after continuous bending cycles.

Prof. Kwanghee Lee said, “Our new approach is expected

to help realize the large-area and mass production of the flexible and

transparent electrodes because it requires simple and low-cost manufacturing

processes. In addition, we hopefully believe the results will

pave the way to commercialization of ubiquitous optoelectronic applications such

as flexible and wearable electronics.”