Media Center

A multimedia mosaic of moments at GIST

GIST Excellence

[Press Release] Prof. Kwanghee Lee"s Team Develops Novel Transfer-Printing Technique for Transparent Electrodes

- 정명식

- REG_DATE : 2015.04.27

- HIT : 765

Study Hoped to Fasten Advent of IoT (Internet

of Things) Era by Enabling Plastic Transparent Electrodes

on Any Desired Surface via Simple Stamping

A Korean

research team has developed a novel method of transfer-printing plastic transparent

electrodes, which have both low cost and

high performance, onto arbitrary surfaces via simple stamping. Through the

versatile integration of high-performance flexible transparent electrodes (FTEs)

with other device components, such as flexible devices and adhesive sensors,

their

research is expected to accelerate the arrival of the Internet of Things era.

The research was led by corresponding

author Prof. Kwanghee Lee of GIST School of Materials Science and Engineering

and by co-first authors Mrs. Nara Kim, a doctoral student at GIST School of

Materials Science and Engineering, and Dr. Hongkyu Kang of the Research

Institute for Solar and Sustainable Energies (RISE). This work was supported by

a grant from the National Research Foundation of Korea, funded by the Ministry

of Science, ICT and Future Planning. The result was published online on April 8,

2015 in Advanced Materials (Title: Highly Conductive All-Plastic

Electrodes Fabricated Using a Novel Chemically Controlled Transfer-Printing

Method).

Conducting plastics (CPs) have been

considered a promising candidate for FTEs to replace conventional transparent

electrodes based on brittle and expensive indium tin oxide, due to their

mechanical flexibility and low-cost solution processability. However, the

necessity of applying a harsh treatment using sulfuric acids to enhance the

electrical conductivity of CPs up to that of ITO makes these cost-effective and

high-performance FTEs unsuitable for application to most underlying layers,

including typical plastic substrates, which would be destroyed by the requisite

strong acid treatment.

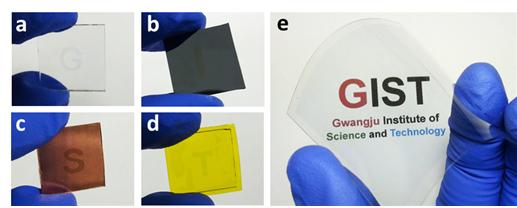

The research

team developed a facile method of transfer-printing the highly conductive

plastic FTEs onto arbitrary surfaces, including typical plastic substrates, by controlling

the adhesion between plastic films and substrates. While the conventional

transfer-printing methods rely on etching the donor substrates for the

detachment of the donor-film interface to “ink” an elastomeric stamp with the

film, the novel transfer-printing method based on the chemically controlled

adhesion at the donor-film interface enabled the simple process of bringing the

stamp into contact with the highly conductive plastic films on the donor

substrates and lifting the stamp away to

produce a stamp that is fully “inked” with the high-performance plastic FTEs, which

is then readily available for transfer-printing onto arbitrary surfaces by using

thin adhesive layers. The plastic FTEs transferred onto various surfaces

exhibited a high visible-range transmittance of 90% and a low sheet resistance

of 45 Ω/sq.

Prof. Lee

said, “Our simple and low-cost manufacturing method for high-performance

plastic electrodes on arbitrary surfaces is expected to expand the scope of

applications of FTEs for the realization of next-generation ubiquitous

electronic technologies, including wearable devices, transparent displays,

adhesive sensors, and transparent antennas, in the coming era of the Internet of

Things.”