Media Center

A multimedia mosaic of moments at GIST

GIST Excellence

[Press Release] Prof. Dong-Yu Kim’s Team Demonstrates Low-Cost, Large-Area Perovskite Solar Cells

- 정명식

- REG_DATE : 2015.02.23

- HIT : 1035

Roll-to-Roll

Fabrication of Fully Slot-Die Coated Perovskite Solar Cells Published in Advanced Materials

Study

Hoped to Expedite Mass Production and Commercialization of Perovskite Solar

Cells

A Korean-Australian joint research team has demonstrated the possibility of low-cost, large-scale mass production of high-performance perovskite solar cells by using a roll-to-roll process with a slot-die coating method. The study is expected to contribute to the commercialization of perovskite solar cells, which are emerging as a promising renewable energy device.

The

research was led by corresponding authors Prof. Dong-Yu Kim of GIST School of

Materials Science and Engineering and Dr. Doojin Vak of The Commonwealth

Scientific and Industrial Research Organization (CSIRO), conducted by first

author Mr. Kyeongil Hwang and other researchers of GIST and CSIRO, and

supported by a grant from the National Research Foundation of Korea under the

Ministry of Science, ICT and Future Planning.

The

research results were online published on January 7, 2015 in Advanced Materials (Title: Toward Large

Scale Roll-to-Roll Production of Fully Printed Perovskite Solar Cells).

Recently,

perovskite solar cells have emerged as promising next-generation solar cells

with a high efficiency of up to 20%, which is comparable to that of commercialized

silicon solar cells. However, perovskite

solar cells have been made by a vapor deposition process or a spin

coating process, and no scalable method has been used to fabricate perovskite solar cells.

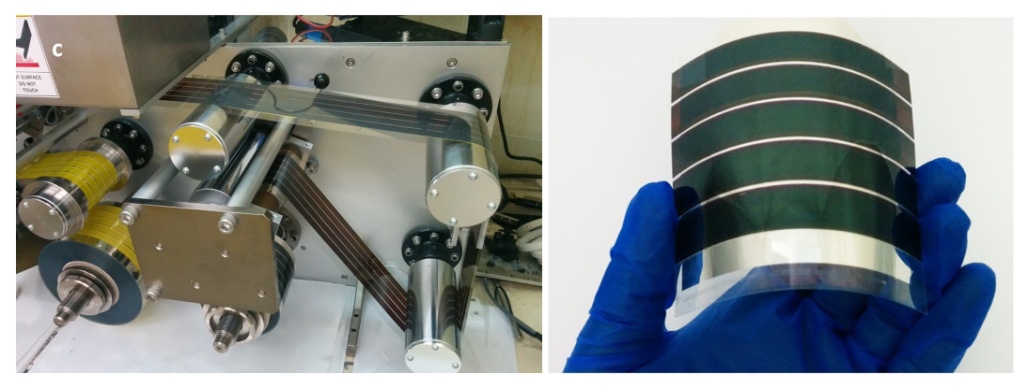

The research team for the first time demonstrated

fully printed perovskite solar cells with a scalable method of slot-die coating

in a roll-to-roll process. By introducing nitrogen gas-blowing to the fabrication

procedure, the wet perovskite film could be quickly dried and be free from

pin-holes, which are an origin of device failure. The perovskite solar cell

devices made with the well-controlled printing process showed an efficiency of 12%,

which is comparable to that of spin-coated devices.

In addition, the research team for the first time

demonstrated perovskite solar cell modules with the size of 40 square centimeters, 400

times larger than the typical 0.1 square centimeter cells made for research

purposes.

Professor Kim said, "Our study clearly shows the possibility of low-cost mass production of perovskite solar cells. It represents the first-ever successful fabrication of a perovskite solar cell module based on a roll-to-toll process, and as such, is expected to provide an important stepping stone towards the commercialization of perovskite solar cells."