Media Center

A multimedia mosaic of moments at GIST

GIST Excellence

[Press Release] Metals with more diverse colors

- 엘리스 리

- REG_DATE : 2017.01.09

- HIT : 912

Metals with more diverse colors

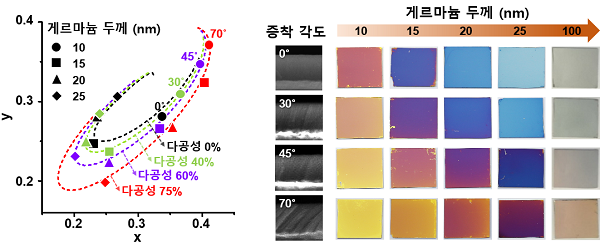

(Figure 1) Sample images of the color values (left), deposition angles, and thickness of samples fabricated using oblique deposition (right). The reflectance of the samples fabricated using the oblique deposition was measured, and the color values were obtained. In the actual sample photograph on the right, the change in color depending on the deposition angle and thickness can be confirmed. The porosity 0%, 40%, 60% and 75% are matched to the deposition angles 0, 30, 45 and 70, respectively.

□ Can I change the color of gold, silver, and aluminum? The National Research Foundation of Korea has announced that a research team led by Professor Young Min Song of the Gwangju Institute of Science and Technology (GIST) and Professor Kyung In Chang of Daegu Gyeongbuk Institute of Science and Technology (DGIST) has discovered that coating metal with nanometer * semiconductors at various angles provided darker and more subtle color changes.

* Nanometer (nm): one billionth of a meter

□ The researchers coated the semiconducting material with a thin layer of nanometer-thick semiconductor on the metal, resulting in strong thin film interference * from light reflected off the surface of the metal and semiconductor. They succeeded in changing the unique colors of metals, such as gold and silver.

* Ultra-thin film: a thin film is less than a micrometer in thickness and cannot be machined, and an ultra-thin film is even thinner. A film of usually several to several tens of nanometers in thickness is called ultra-thin film.

* Thin-film interference effect: Thin-film structure composed of multiple thin-film layers where light reflected from each thin-film layer interferes with each other.

□ There have been previous researches that color changes according to the ultra-thin thickness of germanium semiconductors coated on gold, but the change of color is rapid while being difficult to color deeply.

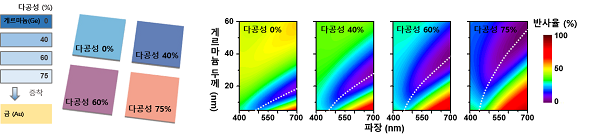

(Figure 2) Porosity ultra-thin structure and schematic diagram (left), change of reflectance according to thickness change of ultra-thin structure with different porosity (right). Various colors can be realized by depositing several nanometers of germanium having different porosities on the gold. As shown in the figure at right, we can see that the movement of the reflection curve (white dashed line) changes with the thickness at different porosity in the reflectance change by simulation. As the degree of porosity increases, the movement of the white dotted line is gradual, which means that the color change with germanium thickness changes more slowly.

□ The researchers coated a thin layer of germanium with a thickness of 5 to 25 nanometers using the oblique deposition method on a gold surface. As a result, various colors such as yellow, orange, blue, and purple could be produced as desired depending on the thickness and deposition angle of the germanium coating.

* Beam Deposition Method: Deposition of material on oblique surface of substrate

* Deposition: a change in the state of a substance or a set of substances from a gas phase to a solid phase

- The oblique deposition method is the method of choice to reduce the high complex refractive index * of the germanium layer. Applying a porous * with a small hole in the germanium by oblique incidence can reduce the complex refractive index.

* Complex refractive index: It is expressed as a complex number with no unit that indicates the characteristic of the medium and describes how light propagates through a material.

* Porosity: A property of having a lot of small pores on the inside or surface of a substance. It means the ratio of empty space, such as holes in a material. In this study, it is applied to medium of ultra-thin structure to realize various colors.

(From left) GIST Professor Young Min Song, DGIST Professor Kyung In Chang,

and GIST master"s student Young Jin Yu

Professor Young Min Song said, "This research has developed a new way to change the color of metals to have a more diverse range than ever before by using an ultra-thin semiconductor with a thickness of 5 to 25 nanometers. It can be applied to solar cells, wearable appliances, displays, metal visual arts, and jewelry that can be used for various purposes such as building exterior walls in the future. "

□ The results of this research were carried out with the support of the Basic Research Program of the Ministry of Science, ICT and Future Planning. Their paper was published in Nanoscale on December 9, 2016.